Profile of SEEKRUN

Suzhou Seekrun Technology Co., Ltd., founded in 2020, specializes in providing diversified intelligent hardware products for ebikes and bicycles. Our mission is to enable users to enjoy a better and more fun cycling experience.

We have a professional team, with R&D personnel accounting for over 50% of our workforce. Core members bring 20 years of industry expertise, allowing us to continuously develop innovative and improved intelligent hardware products for our customers.

Currently, we offer two main product series: the Smart Wireless Dropper Seatpost and Display products. The Smart Wireless Dropper Seatpost series includes both competition-grade and consumer-grade models, compatible with mountain bikes, gravel bikes, cargo bikes, city bikes, and more. Our Display product range covers centrally-mounted, side-mounted, and embedded displays, among other types, and can be deeply customized according to client requirements. All these products are designed to deliver an enhanced riding experience.

After years of development, we now operate two major bases:the headquarters R&D base and the production & testing base, with a total area of over 10,000 square meters. We have obtained multiple quality management system certifications and are equipped with comprehensive testing and production facilities, including several proprietary testing and manufacturing equipment developed in-house. This enables us to provide tailored intelligent hardware solutions for a wide range of customer needs.

Vision

Vision

To become a world-class brand with intelligent interconnection at its core

Mission

Mission

To provide systematic scenario-based solutions

Values

Values

People-centered development strategy; To be a value contributor, to be united as one and to be hardworking and enterprising

Testing Capability

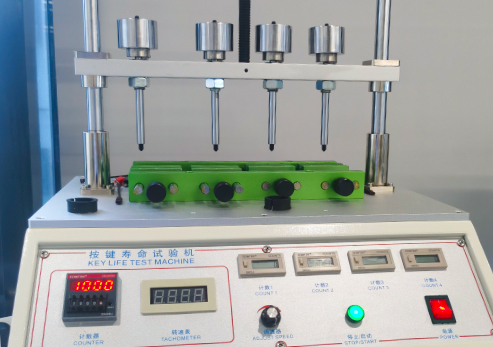

Press life test

Insertion force test

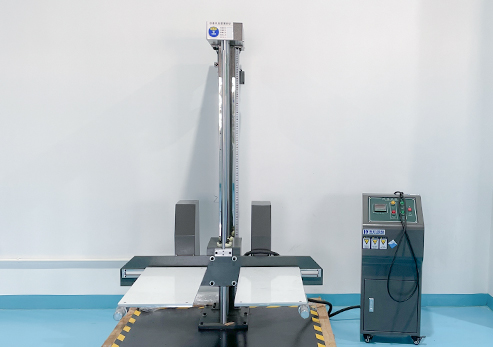

Drop test

Waterproof test

High temperature test

Constant humidity and constant temperature test

Operating temperature test

Metallographic grinding test

High-low temperature cycles test

Thickness meter test

Voltage resistance test

Anti-static interference test

Fiber hardness test

Salt spray test

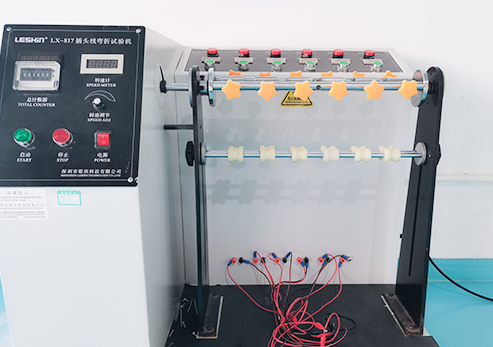

Swing test

Vibration test

DC power supply test (overvoltage test)

UV resistance test

Riding test

Endurance test

Press life test

To confirm the hand feeling during the pressing course and test the functions as normal after 100,000 times of cyclic press test

Insertion force test

To verify that the product can operate effectively after continuous plugging and unplugging of the connector

Drop test

To verify that the product can run reliably without any abnormal performance after the installed product falls down

Waterproof test

To verify whether the product meets the designed IPXX waterproof rate requirement

High temperature test

To verify that the product can operate stably and reliably under high temperature conditions

Constant humidity and constant temperature test

To verify that the product can operate stably and reliably under high temperature and high humidity conditions

Operating temperature test

To confirm that the product will not cause burns to the human body during continuous reliable operations

Metallographic grinding test

To make slicing and grinding analysis for defective products

High-low temperature cycles test

To verify that the product can operate stably and reliably when the temperature continues to change

Thickness meter test

To test h the film thickness of electroplated parts meets the drawing requirement

Voltage resistance test

To verify that the product can operate reliably in an unstable voltage environment

Anti-static interference test

To verify that the product will not be subject to human electrostatic interference and to have abnormal running

Fiber hardness test

To verify the hardness of rubber and to confirm that the material performance meets the requirement of the drawing

Salt spray test

To verify that the simulated products can operate stably and reliably in coastal cities and other cities

Swing test

To verify that no current cutoff occurs to affect product reliability after the cable swings

Vibration test

To verify that in simulation the product can still operate stably and reliably when subjected to vibration during the ride

DC power supply test (overvoltage test)

To confirm the reliability of the product under unstable voltage condition

UV resistance test

To verify that in simulation the product can operate stably and reliably overvoltage test outdoor sun exposure

Riding test

Outdoor riding test is conducted to verify that the product can operate stably and reliably under any real condition

Endurance test

To confirm that the new product can operate reliably during a long period of continuous operation.

SEEKRUN focuses on the enjoyment of sports, caring safety, and supporting the growth of partners. Currently, in the Ebike industry, SEEKRUN has developed a complete product matrix of intelligent hardware, including displays.

Copyright © SEEKRUN All Rights Reserved Sitemap